PRODUCTION TECHNOLOGIES

Frame houses are one of the most promising technologies for the construction of country houses and cottages. Today it is one of the most popular technologies for the construction of low-rise buildings in the world. This technology is the main type of low-rise construction in many developed countries of the world: USA, Canada, Japan, Scandinavia, Finland, Germany, etc.

In most countries, frame-panel houses are being built for the implementation of national housing programs — optimal in terms of price, quality, construction time, and service life.

The production of frame-panel houses is organized in such a way that the components of a low-rise house (walls, partitions, floors, roof panels and other elements) are manufactured in the factory in accordance with the previously developed design documentation.

The energy efficiency of houses from the company Zenvile

The company Zenvile specializes in the production of energy-efficient homes using modern technology, which involves the assembly of buildings from prefabricated elements. Structural elements are made at the factory (external walls, internal partitions, floors, roof panels, etc.). Structures are delivered to the place of installation of the house by the road and mounted on a ready foundation within 1 – 3 days. For the production of elements of the house, modern materials and technologies are used, which determines the energy efficiency of buildings. This allows the owner to save a significant amount on heating, air conditioning, and associated costs.

For us, designing an energy-efficient home means creating and implementing a set of advanced design and engineering solutions that will reduce operating costs throughout the entire period of operation. Turning to our company you will receive carefully designed and high-quality work on the design and production of energy-efficient homes. Taking into account the fact that at present energy efficiency is one of the basic characteristics of prestigious high-quality housing, this efficiency becomes one of the key arguments for selling houses from the company Zenvile in the secondary market.

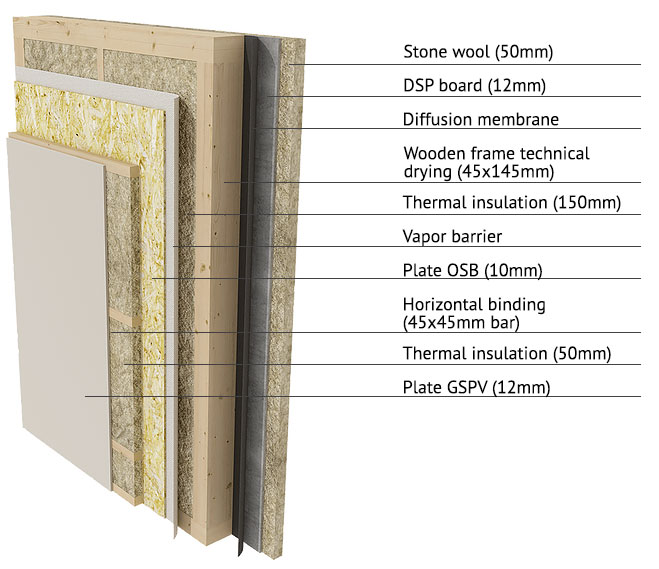

The walls of the frame house have a layered structure. The base is a wooden frame of planed sawn timber that has undergone technical drying, with a moisture content of 12-14%. Next, the frame is filled with non-combustible stone wool insulation. The applied insulation does not shrink and does not lose its properties during operation. Sufficient plate density prevents convection, so heat transfer resistance is maintained even in very cold winters.

Outside, a diffusion membrane is laid on the frame, which, due to its unique properties, ensures the diffusion of steam, but prevents the passage of moisture. Then the wall is sheathed with a cement-bonded particleboard (DSP), 12 mm thick. DSP is an environmentally friendly material. DSP does not contain phenolic, formaldehyde and other toxic compounds. The main chemical binder is cement. The plates are made by pressing a molded mixture consisting of softwood chips, portland cement, minerals and water. Plates not only give the wooden frame additional rigidity, but also serve as protection against weathering.

At the request of the Customer, a heat-insulating layer for thin-layer plaster facades is mounted on a DSP plate – a non-combustible slab of the brand PAROC LINIO 20, having a thickness of 50 mm.

On the inside, a vapor barrier is laid on the frame, which serves to protect the insulation, the wooden frame and other layers from moisture and condensate accumulation, which is formed due to the difference in temperature conditions inside and outside the room.

Next to the vapor barrier is mounted plate OSB-3 (10mm), which gives the supporting frame diagonal rigidity.

To prevent the occurrence of cold bridges, as well as for installation of engineering networks, horizontal piping (45x45mm bar) with horizontally directed thermal insulation, 50 mm thick, is used.

Gypsum chipboard is used as the inner lining; it is moisture resistant (GSPV), 12 mm thick. GSPV panels distinguish among competitors its undeniable advantages – durability and practicality, high rates of fire safety and fire resistance, environmental friendliness, biostability and many other factors. They allow us to call the gypsum chipboard the best at the moment analogue of drywall. The production technology of GSPV eliminates adhesives and resins in the composition; this determines a high class of environmental friendliness and safety for human health.